Pickleball is the fastest-growing sport in the U.S., and as more players join, equipment innovation has followed suit. Among the most crucial advancements is the pickleballs itself—evolving from basic plastic toys to high-performance sports gear.

Today, technology is driving materials, aerodynamics, and sustainability improvements, enhancing gameplay and environmental impact. Let’s explore how pickleball balls have transformed over the years.

Early Days: From Wiffle Balls to Pickleball-Specific Designs

The First Pickleballs

When pickleball was invented in 1965, players used Wiffle balls, designed for baseball practice. While functional, these balls lacked durability and consistent flight patterns. Soon, the Cosom Fun Ball, a plastic ball with evenly spaced holes, became the preferred choice.

Challenges with Early Balls

- Durability Issues – Balls cracked easily after extended play.

- Inconsistent Bounce – Uneven holes affected flight paths.

- Lack of Standardization – No official ball design for tournaments.

As pickleball’s popularity grew, manufacturers developed purpose-built balls for the sport, improving their construction and performance.

Technological Advancements: Better Materials & Durability

High-Performance Plastics

Today, pickleballsare made from durable plastics like polypropylene (PP) and polyethylene (PE), offering better resistance to cracks and environmental wear. Outdoor balls are made from firmer materials to withstand rough court surfaces, while indoor balls are softer for improved control.

Seamed vs. Seamless Balls

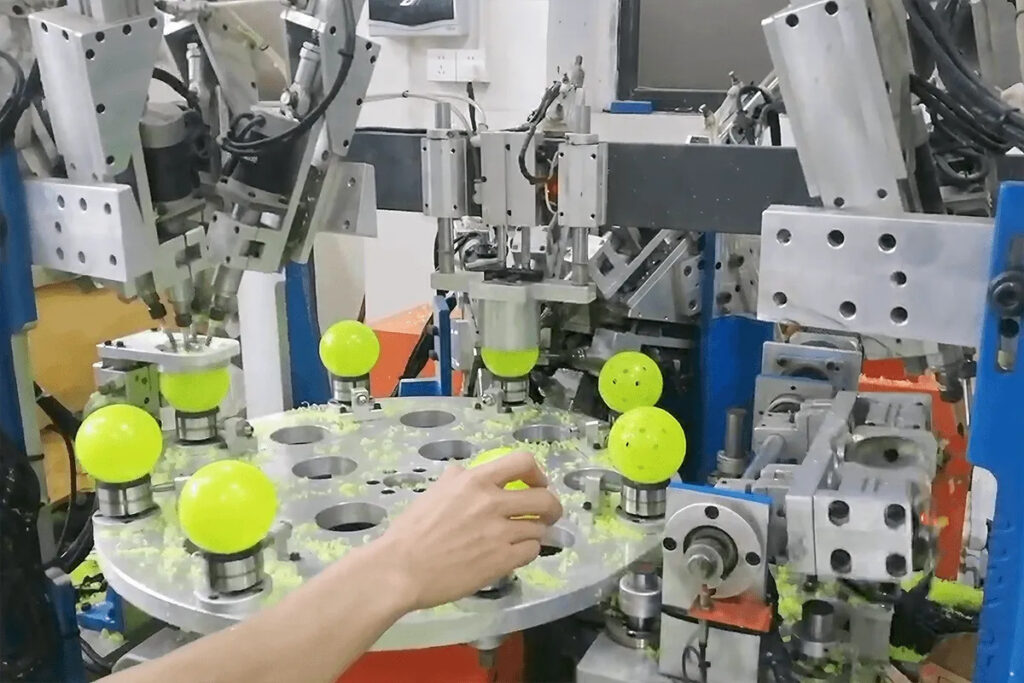

- Injection Molding – A precise and efficient process that ensures consistent shape, durability, and optimal flight performance. Evolute Pickleball uses advanced Injection molding techniques to minimize weak spots, resulting in high-quality, tournament-ready pickleballs.

- Rotational Molding – While it produces seamless balls, it is less commonly used due to longer production times and potential inconsistencies in wall thickness.

Aerodynamics & Hole Design

Pickleballs are now precision-engineered, with optimized hole patterns to enhance flight stability:

- Outdoor balls: Typically 40 smaller holes for wind resistance.

- Indoor balls: Larger holes (26-32) for a softer bounce and better control.

The Shift Toward Sustainability

The Environmental Impact of Pickleballs

With an estimated 500 million balls produced yearly, waste has become a concern. Standard plastic balls cannot be recycled easily, leading to massive landfill contributions.

The Rise of Eco-Friendly Pickleballs

- Recycled Plastic Balls – Made from post-consumer materials while maintaining USAPA standards.

- Biodegradable Options – Some manufacturers are exploring plant-based polymers to reduce waste.

- Longevity Improvements – New materials aim to increase ball lifespan, minimizing replacements.

What’s Next for Pickleballs?

Enhancing Durability

Manufacturers are developing longer-lasting balls with advanced polymer blends, reducing the need for frequent replacements and cutting plastic waste.

Noise Reduction

As pickleball expands into residential areas, quiet pickleballs are being designed to lower impact noise while maintaining performance.

Fully Sustainable Models

Future innovations may include 100% biodegradable or recycled pickleballs, ensuring a greener future for the sport.

The Game is Changing And So Are the Balls

Pickleball is evolving, and so is the equipment used to play it. What started as a simple adaptation of a plastic toy has become a highly engineered piece of sports gear.

With advanced materials, improved aerodynamics, and sustainable alternatives emerging, the future of pickleballs looks promising. As the sport grows, so will the innovations, ensuring players get the best experience while making environmentally responsible choices.